Laserstrahlschweißen im Vakuum

Ihr Nutzen durch unsere Technologie

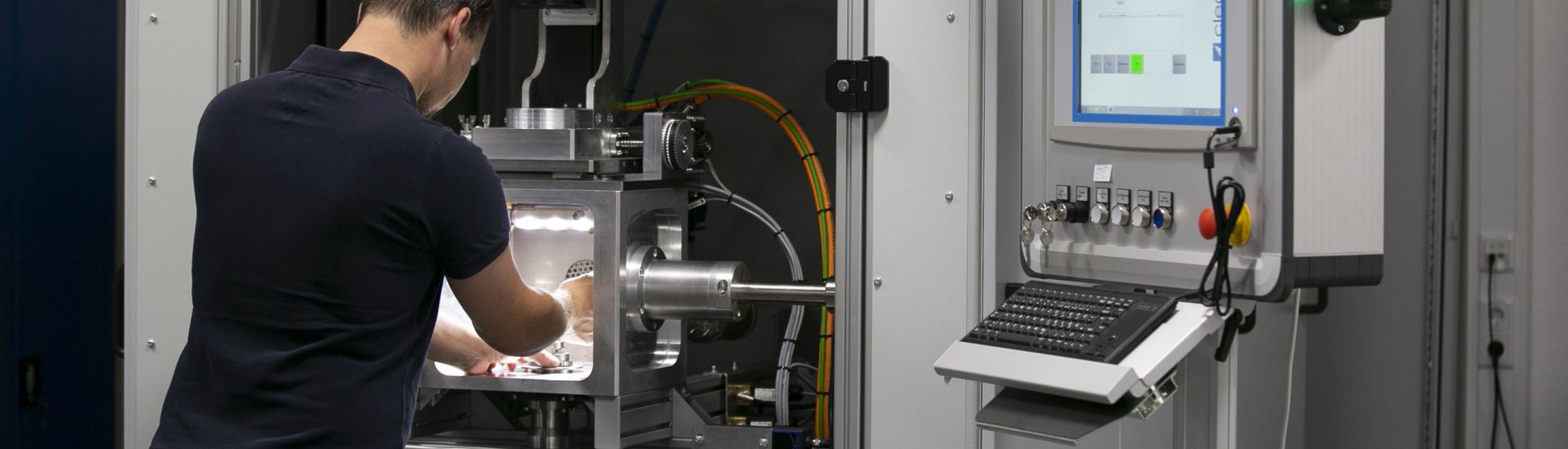

Steigerung der Qualität

Poren- und rissfreie Schweißnähte auch bei schwierigen Werkstoffen und Mischverbindungen.

Vermeidung von Spritzern

Keine anhaftenden Schweißspritzer und Vermeidung von Bedampfung und Oxidation.

Steigerung der Produktivität

Erhöhung der Einschweißtiefe oder Reduktion der Laserleistung bei gleicher Einschweißtiefe. Vermeidung von Verzug.

Ökonomisch & Ökologisch

Verwendung kleiner Laserquellen. Keine Druckluft und erhebliche Reduktion des Schutzgasverbrauchs.